Ground Stones

Ground Stone Artefacts from the Neolithic Settlement of Avgi: A Preliminary Report

Introduction

Recent large-scale excavations (2002-2008) at the Neolithic Settlement of Avgi (c. 5650-4500 BC) brought to light one of the largest ground stone assemblages from Neolithic Greece (Bekiaris 2008), counting more than 5000 artifacts. The assemblage consists of ground stone tools, raw materials for manufacture (unused boulders, cobbles and pebbles), the byproducts of such manufacture (flakes), as well as a variety of other ‘non-tool’ ground stone objects (e.g. structural stones, vessels, figurines, ornaments). The study of Avgi’s ground stone artifacts follows a contextual perspective, aiming at understanding their technological characteristics (raw materials, manufacture, consumption, discard), explore their participation in various prehistoric chaînes opératoires and investigate their role within different temporal, spatial and social contexts.

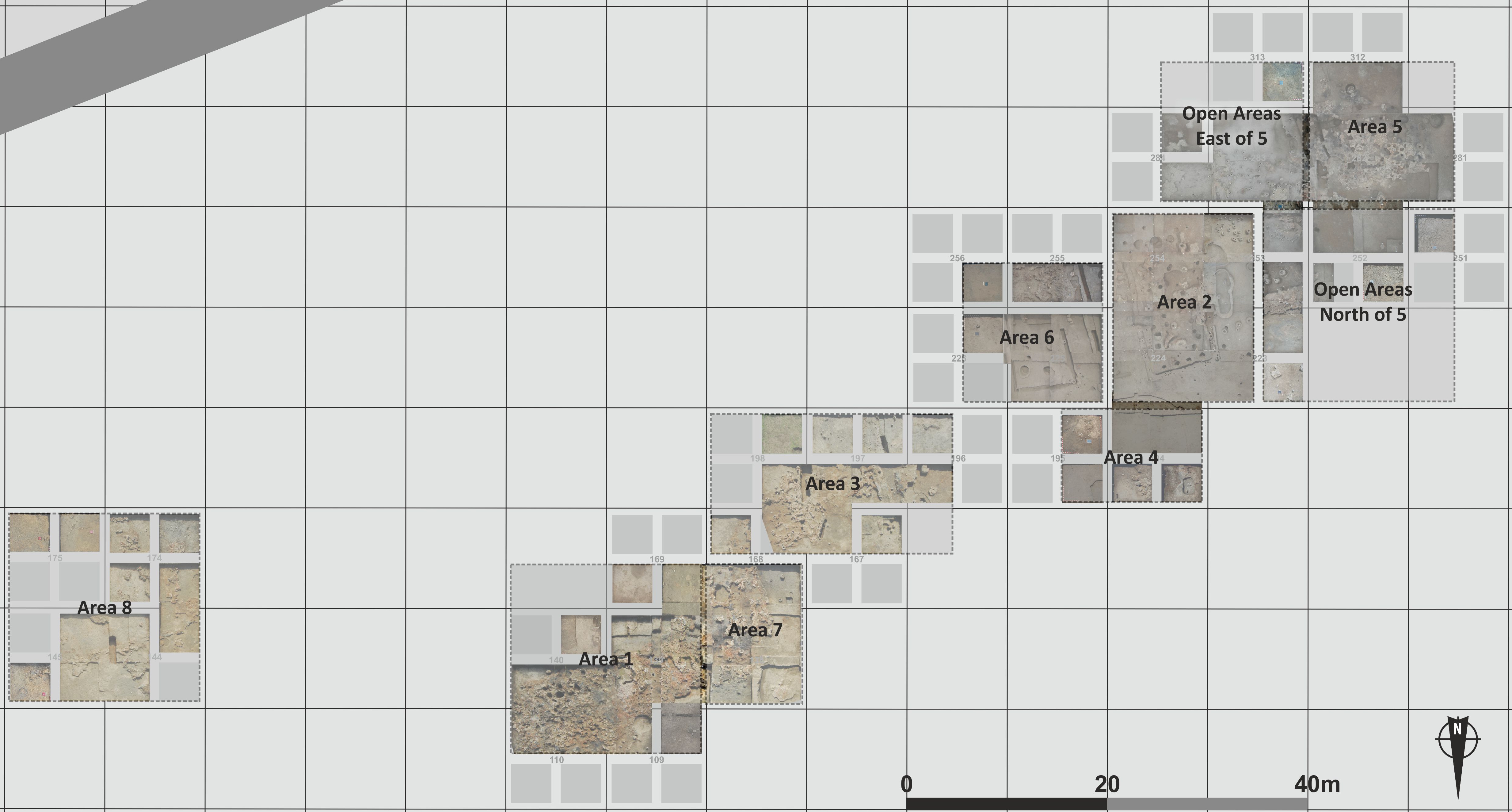

Fig.1. The excavated areas of the site.

The study

The analysis of the material began in 2009 and continued more systematically in 2011 with a 4 month study period. During these study seasons approximately 700 ground stone artifacts have been recorded and analyzed from a technological and typological perspective. The items studied so far came from stratified neolithic deposits excavated at the site’s West Sector, mostly during the 2006-2007 campaigns. Most recorded artifacts (c. 80%) were recovered from an extended open area identified as ‘East of Area 5’ (Fig. 1), while for the moment fewer (c. 15%) are the analyzed ground stone objects from ‘Area 5’, the study of which remains incomplete. A very limited number (4%) of the recorded artifacts, specifically edge tools, came from other areas of the West Sector and were included in the study in order to provide a wider picture of that specific tool-type. The open areas ‘East of Area 5’ and ‘Area 5’ yielded a huge quantity of ground stone artifacts (c. 1500 pieces in total) deriving from various Neolithic deposits and contexts, such as house destruction layers, house floor deposits and floor substrata, open areas, pits of various forms and types and foundation trenches, dating to all three occupational phases of the settlement, AVGI I (MN/LN I), AVGI II (LN II) and AVGI III (LN II). A considerable number of these artifacts, mostly lower grinding stones and hand-held grinders, were located in situ and in the vicinity of outdoor thermal structures (Fig, 2), such as ovens and hearths, in spatial relation with other stone tools, pottery, plant foods and animal bones (Bekiaris 2008), providing a great opportunity for a contextual study of ground stone technology in the Neolithic Settlement of Avgi.

Fig. 2. Grinding slab and grinder at an outdoor area of the phase AVGI II.

This paper summarizes the results of the first study periods and presents the main technological characteristics of the ground stone artifacts from the Neolithic Settlement of Avgi. Various stages of the analysis, such as the petrographic identification, the statistical and contextual processing of the sample are still incomplete. Therefore, the observations made below should be considered preliminary.

Ground Stone Technology

Based on their technological characteristics the ground stones from Avgi have been classified to the following categories: grinding/abrasive tools (69% of the artifacts analyzed so far), edge tools (7%), miscellanea (7%), percussive tools (6%) and debitage (5%). Artifacts that survive in an extremely fragmented state and lack any diagnostic features were classified as indeterminate (6%). Each category is further divided into smaller groups, according to similarities in the morphological or functional features of the artifacts.

Grinding/abrasive tools

The dominant category of the assemblage is that of grinding/abrasive tools. This can be sub-divided into several groups: hand-held grinders, stable grinding stones, pebble tools and grooved abraders.

The grinders of Avgi are mobile hand-stones of an elliptical, circular or rectangular shape. They have been used with one or two broad flat, slightly convex or sloping faces, in order to perform abrasive actions. Most grinders (>80 %) are the products of an expedient technology (Fig. 3); water worn sandstone and limestone cobbles, collected from the nearby Aliakmonas River (5 km. distance from the site), bearing no evidence of manufacture or any other modification, are dominant in the group (Fig. 4).

Fig. 3. Discoidal grinder with abrasive wear on both faces.

Fig. 4. Elliptical grinder with abrasive wear on both faces. Exposed to fire.

Only some of them (c. 20 %) have been submitted to pecking and rarely to grinding, in order to reduce their original sizes, as suggested by manufacture wear traceable on the periphery or their sides (Fig. 5, 6). The active faces of few specimens have been rejuvenated via pecking, while some of them were probably accidentally broken during this procedure. Use-wear patterns include traces of abrasion (flattened grains and loose particles in the specimens subjected to a stereoscopic analysis), which in the vast majority of cases is accompanied by sheen, covering portions of the working surfaces. Subtle scratches are preserved mostly on the limestone grinders, allowing us to restore the tool’s strokes while it was used. Reciprocal movement is usually encountered in the elliptical/rectangular grinders, while multi-directional movement on the circular implements. Most grinders are of sizes suitable to be manipulated with only one hand, with the maximum length (of the intact tools) ranging between 10-13 cm and the width between 5-7 cm.

A distinct sub-group of grinders deserves a closer look. These grinders are all made of coarse grained sandstone and they were the products of a complex manufacture sequence which employed the techniques of flaking, pecking and grinding. Their sizes and weight (> 2 kg) along with their raw materials and manufacture wear resemble the smaller specimens of the stable grinding tools. However, these were certainly handheld and indeed used with two hands, because of their loaf-shaped unused face and their narrow, although oblong, workface, features that would make their use as passive implements inconvenient. They all show traces of abrasion and sheen on their active faces along with evidence of multiple episodes of resharpening. Considering their weight, raw material and use-wear these grinders would have been suitable for grain processing.

Fig. 5. Two-hand elliptical grinder with abrasive wear and spots of sheen on its face.

Fig. 6. Two-hand elliptical grinder with abrasive wear on its face.

Grinders are usually perceived as the upper, active components of the lower and stable grinding slabs (Adams 2002), used together for the processing of various substances, such as grain or pigments. However, it is highly possible that many grinders could have also acted independently of their passive components when needed.

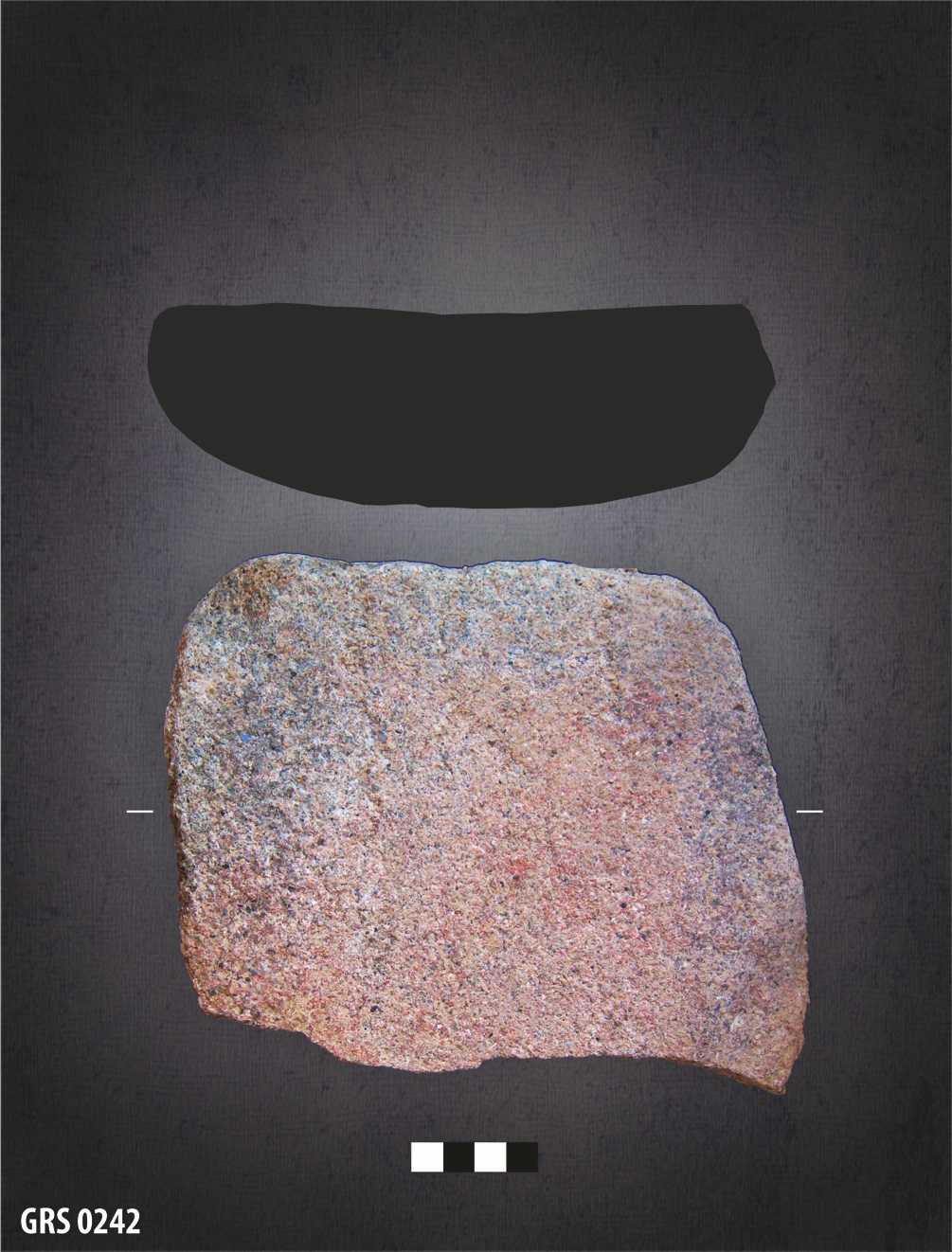

Grinding slabs (Fig. 7) are lower grinding stones that remain stable during use. In Avgi they are made of coarse or fine grained sandstones with sharp intrusions that would easily cut through and pulverize the working materials. All the water-worn boulders and cobbles, collected from the Aliakmonas riverbed, were transformed into effective passive tools via the techniques of flaking, pecking and grinding. Flaking and pecking were extensively used for creating the broad, unbounded work faces of the tools, while pecking was also applied in order to rejuvenate the work faces when they became dull. The same techniques were used, when needed, for the shaping of the base in order to increase the tool’s stability on the ground or at the user’s lap. Pecking marks, almost eliminated by succeeding grinding wear were also located on the sides of a few specimens. The purpose of this procedure could be to make the sides of the tool vertical, in order to store it on a standing position near the house walls or elsewhere while not in use. Most of the stable grinding stones (>90 %) have an open broad and unrestricted surface which has been used in a passive abrasive mode. The faces are either flat or slightly concave in transversal cross-section, an attribute strongly affected by the morphology of the upper grinder (see Adams 2002). Their sizes are relatively small (cf. Stroulia 2010) with the length of the intact specimens ranging between 18-25 cm. and their width 12-15 cm. Their thickness also varies between 0.30-0.90 cm. Their weight varies between 5-10 kilos. These dimensions indicate the portable character of the passive tools that could have been shifted among houses and yards, depending on the user’s will or the social character (communal/private) of the task being accomplished (see Tsoraki 2007).

Fig. 7. Grinding slab with an open broad face, bearing abrasive wear.

A very limited number of the analyzed grinding slabs (<10 %) are characterized by the presence of a basin on one of their faces and of a trough running parallel to the long-axis on the other (Fig. 8). Both cavities were strategically designed in order to ‘trap’ the working substance while the handheld implement processed it by performing circular or reciprocal strokes. The passive tools with cavities are only encountered in pits of the phase AVGI III, probably suggesting a shift in grinding practices during the life of the Neolithic settlement.

Fig. 8. Grinding slab with a basin on one face and a trough on the other.

The use wear of the grinding slabs includes traces of abrasion (64%) often accompanied by the presence of sheen (36%). Grinding slabs could have been used for processing of edible substances, such as plant foods (e.g. cereal grains) or for pigment processing. Traces of red pigment (Fig. 9) were identified only in a few passive tools (7%), with evidence suggesting that this was a secondary function rather than the task they were originally designed for.

Fig. 9. Grinding slab with an open broad face, bearing abrasive wear and traces of red pigment.

Another rich subset of the ‘grinding/abrasive’ category is the pebble tools group. This includes expediently designed limestone and sandstone pebbles (a threshold value of <7 cm was followed in order to classify a rock as ‘pebble’) that were used with their faces, sides and edges in an active abrasive mode. They come in many shapes (elliptical, oval, circular, discoid) and sizes (the smaller specimens are of a length <2 cm) and most of them exhibit high sheen on their work faces, often accompanied by subtle scratches, running vertically or diagonally to the tool’s long axis. Traces of clay were also identified through stereoscopic examination of some specimens. These tools were probably used in order to alter the texture of surfaces of other objects, specifically to smooth or polish them. Such tools, commonly characterized as polishers, have been associated with pottery burnishing or with the accentuation of the appearance of wood or bone (Wright 1998; Adams 2002).

Finally, some tools are characterized by the presence of a deep or narrow groove on one of their faces (grooved abraders). The groove has a U or V shaped cross-section and suggests the use of the stone as an abrader in order to create and sharpen the pointy ends of bone or wooden tools or smooth the body of wooden shafts (Adams 2002).

Edge tools

This category comprises stone implements that have acquired an acute edge on one of their ends through deliberate modification. Also known as ground stone celts (e.g. Stroulia 2003; Tsoraki 2011), these tools were originally hafted to a shaft made of wood, bone or antler. The category of edge tools also includes a few celt pre-forms and various flakes, classified as the byproducts of celt manufacture. The detailed identification of the raw materials is scheduled for the upcoming study season, but macroscopic observations indicate that most of them were made of metamorphic rocks, particularly serpentinite. Like in the nearby neolithic lake-settlement of Dispilio (Melfos and Stratouli 2002; Stratouli 2002), the inhabitants of neolithic Avgi have possibly also acquired serpentinite from Mavro Vouno at Maniaki region, at a distance of about 10 km. from the site.

Fig. 10. Edge tool, totally burnt.

All edge tools (Fig. 10) are the products of a standardized, complex and time consuming chaîne opératoire. The techniques of flaking, pecking, sawing, and grinding have been exploited in order to manufacture and repair the edge tools, while great effort was invested in order to give them a lustrous appearance through polishing. Flaking and pecking occurred at the earlier stages of the production sequence. As suggested from the celts that were left in a roughed-out form, flaking was used both for the initial reduction of nodules and to some extent for redesigning a celt. Pecking was practiced more often than flaking, as in other similar assemblages from Neolithic Greece (e.g. Stroulia 2003; 2010; Stratouli 2002; Tsoraki 2011). Pecking marks are usually preserved on the celts’ sides and rarely on their bodies, where they were probably obliterated from the subsequent stages of grinding and polishing. All edge tools have been submitted to grinding and polishing, practices that probably required great effort and skill in order to be concluded. Besides erasing the traces of all previous production stages (flaking, pecking and sawing) and perhaps the practical purpose that the smoothness of the tool would have served (e.g. to penetrate the working material easier), these time-consuming stages had undoubtedly an additional aesthetic outcome. The accentuation of the rocks natural color and the glossy appearance of many tools could also have symbolic meaning and social connotations (see Stroulia 2010; Tsoraki 2011) that will be further discussed as the study progresses. The technique of sawing was involved mainly in redesigning and repairing celts. It was used in order to split a tool in half and reduce its overall size when it was refashioned. Traces of sawing are visible on the margins of mostly medium-sized and rectangular edge tools, suggesting that these had probably resulted from larger redesigned implements.

Fig. 11. Edge tool at a stage of redesigning.

The presence of half-finished celts and flakes (originally classified as debitage) indicates that some stages of the production sequence took place within the residential sector of the neolithic settlement. A small number of the analyzed flakes seem to be the outcome of an initial reduction process. These are all serpentinite flakes, which were found together at the exact same spot at an open/midden area of the West Sector, reflecting with certainty a single reduction episode. All the other studied flakes are the products of redesigning/repairing sequences, since they remove already worn surfaces. In addition to this, most of the half-finished edge tools represent already made celts which are on the stage of redesigning (Fig. 11). Therefore, we cannot be certain if all stages of celt production occurred systematically on the habitation area of the settlement. Such activities are ethnographically known to occur off-site, near streams, where sand and water, which are essential for celt manufacture, are abundant. However, the secondary processing of these tools was certainly practiced within the settlement.

The edge tools of Avgi exhibit great variability in their morphological characteristics. The complete specimens range in length between 3.3-10 cm, in width between 0.90-5.2 cm and in thickness between 0.70-3.6 cm. Given the fact that almost every celt shows traces of multiple episodes of resharpening, redesigning and/or recycling, I perceive their dimensions mostly as the result of these processes, rather than their original design (also see Stroulia 2003; 2010). Their shapes are usually sub-triangular, trapezoidal, rectangular or sub-rectangular, while their profiles are either symmetrical or asymmetrical. Their transversal section is oval, plano-convex or rectangular.

Their use wear, mainly identified through stereoscopic examination, consists of traces of heavy and light chipping, flattening and rounding located on the cutting edges, accompanied by subtle and dense scratches running diagonally or vertical to the edge. This wear was caused by the resistance of the worked materials, probably wood or bone, to the tools that penetrated them. A large number of the edge tools have been used secondarily in an active percussive mode. We should note here that all celts in Avgi exhibit use-wear, irrespectively of their dimensions, their glossy appearance or the effort taken during their manufacture, proving that size and looks do not affect the utility of such tools (as in Stroulia 2010; Tsoraki 2011).

Percussive tools

The category includes a rather small number of expedient rocks that share a globular shape and have been used in an active diffuse percussive manner with their faces and edges. The globular shape of these tools can be attributed to natural factors, as water-rolled pebbles and cobbles were collected from the Aliakmonas streambeds in order to be used as percussion tools. At some specimens the globular shape could be the result of the repeated percussive use, preformed with all the faces of the tool. The sizes of these tools range between 3-10 cm. The smaller specimens are considered to be exhausted since they cannot be held securely, in order to perform accurate strokes. Heavily beaten surfaces with scars and fractures are the distinct features of the percussive tools (Fig. 12). Such implements could have been used in many activities involving the breakage or the reduction of materials (Adams 2002).

Fig. 12. Percussive globular tool with impact fractures and scars on all its faces.

A subset in the percussive tools category should be discussed separately. This includes tools that were used in an active percussive mode, with one or two opposite ends, that were formed through deliberate modification. Their raw materials and manufacture techniques (pecking and subsequent grinding) of the end tools resemble those of the edge tools, but their sizes and globular shapes distinguish them from the celts used in a percussive mode when they became dull. Similar tools are reported from Francthi (Stroulia 2010), Megalo Nisi Galanis (Stroulia pers. comm.), Dispilio (Stratouli 2002) and Makri (Bekiaris 2007). Their ends are usually slightly convex in plan, and in some cases flat or even slightly concave. Sometimes different facets, flat and inclined in plan, were created at the same end, suggesting that the tool stroke the worked material at an oblique angle (Stroulia 2010).

Some tools of this subset combine the active percussive use with an active abrasive one. Those tools seem to have been originally designed to serve both functions. Again, they are pretty much globular in shape, oval or sub-rectangular in plan, but they have a triangular transverse section. These are the only tools so far with hand-grips, modified areas that enabled the secure holding of the tool while in use. They were used in a percussive manner with both ends, and in an abrasive mode with one or two unbounded broad faces.

Fig. 13. Tool with both abrasive and percussive wear on its faces and ends.

Miscellaneous

This is a rather heterogeneous category. It comprises ground stone objects that served a ‘non-tool’ function (as in Stroulia 2010), which means that they were not involved in the processing of other materials. Many different subsets were included in this category: maceheads, ornaments, sling-shot bullets, stone vessels, closures and structural stones. So far, very few specimens of each sub-type have been analyzed, since such objects are rarely encountered in the archaeological record. Therefore, their presentation will have to wait for future publications.

Contexts of consumption and discard

As mentioned earlier all context types at Avgi have yielded large numbers of ground stone artifacts. So far the excavation contexts were classified in the following types: buildings (including building collapse layers, floor deposits and floor substratum), open/midden areas and pits. The vast majority of the analyzed artifacts (c. 80%) came from open/midden areas. Fewer are the implements recovered from the interior of pits (c. 15%), while, for the time being, only a limited number of ground stone objects (c. 5%) can be associated with building deposits. Although the spatial and chronological distribution of the analyzed artifacts is still in progress, preventing the detailed, contextual examination of individual artifact classes, there are some preliminary observations mentioning.

The most obvious contrast occurs between buildings and open areas of the Avgi I phase. If the communal areas have yielded a great repertoire of numerous ground stone tools, pointing to a set of regularly practiced activities, the houses are almost empty of ground stone equipment. In fact, only grinding slabs seem to be a common and perhaps standard attribute of some houses, while the rest of the household’s ground stone toolkit remains, for the moment, unknown. Moreover, the co-existence of grinding slabs and charred grains in the Avgi I buildings indicates that food processing was a regular activity, practiced, to some extent, at a domestic context. A small grinding slab was found resting on the floor of Building 2a at the West Sector, along with small concentrations of grain seeds and legumes (Margariti 2007). Most of the seeds were at an already processed stage (dehusked and pounded) and they were probably kept stored in the house, waiting to be cooked and consumed. It is tempting to link the grinding slab with the processing of these seeds, but such results will have to wait for the completion of the ground stone analysis. The association of grinding slabs and seeds is better documented in Building 5, at the SW part of the West Sector. A small pit, interpreted as an interior storage feature of Building 5, has provided large quantities (> 5 kg in total) of grain. The pit was sealed by the burnt debris of the collapsed Building and its contents were exposed to fire during the destruction episode. Apart from the grain, a small grinding slab, very similar to that of Building 2a was found at a vertical position in the pit’s walls. The grindstone was probably stored in the pit together with the grains, in order to be used for their processing at a later stage. Such practices may reflect the value of common, everyday tools, which are often thought to be mundane and ‘free of symbolic meaning’ (Perlès 1992). The link of grinding slabs with food-processing activities, plant foods, and storage and their occurrence in domestic contexts, will be further investigated in the future.

Another significant difference emerges if we compare the presence of ground stones in occupation areas (open/midden layers and buildings) of the phases Avgi I and II, with the pits of Avgi III. Although grinding/abrasive tools overwhelm every other category in any context type and phase, it is peculiar that the pits of Avgi III host almost exclusively grinding/abrasive tools, with few exceptions of other tool types, mostly edge tools. For instance, Pit 109401 in the East Sector provided more than 70 ground stone tools, among which a great repertoire of different types of grinders and grinding slabs and some pebble tools. The same happens with pits from Area 5 (e.g. Pits 282104, 283303, 2823312101) in the West Sector, although their ground stone contents where much more limited than that of Pit 109401. This preference of depositing grinding tools in the pits of Avgi III phase must be further attested and investigated through multiple criteria, such as the strategic or expedient design of the deposited tools, the origin of their raw materials, their degree of use, the general contents and interpretation of each pit etc.

More insights about ground stone consumption and discard practices in Neolithic Avgi can be gained by examining the material from the open area ‘East of Area 5’, since the analysis of its ground stone finds has been completed. This open, extended area has yielded 452 ground stone tools all from stratified neolithic deposits. From those the 25% came from Avgi I deposits, 71% from Avgi II and only 4% from Avgi III. These variations are completely compatible with the amount of deposits removed from each phase.

All artifact classes are represented in the phases Avgi I and Avgi II of the open area, although with some noticeable differences. Edge tools, for instance, occur at very low rates in Avgi I, not only in this area, but on the whole West Sector. This is rather peculiar, since wood has been extensively used as a construction material in the timber framed buildings of Avgi I and requires further investigation by future research. However, it is possible that at this phase woodworking activities were practiced at other parts of the neolithic settlement, perhaps on the periphery, away from the habitation area, or even off-site or that the final deposition of woodworking tools followed different taphonomic pathways. At Avgi II, an expansion of the ground stone objects which are the products of a formal production sequence, including edge tools, end tools, stone vessels and maceheads, is evident, while the variety of the expediently designed tools (i.e. grinders, polishers) also broadens. The widening of the ground stone inventory during this phase may be linked to an expansion of the activities hosted at the neolithic village of Avgi or, conversely, it could be linked to a need for a more detailed toolkit, reflecting a more specialized character.

Interesting patterns emerge from considering the preservation of the ground stone tools, leading to certain remarks on taphonomy. Most Avgi I tools survive on an extremely fragmented state (<1/2 of the original implement), suggesting that they were probably deposited in that particular area of the settlement. The random presence of broken raw materials and few performs without the occurrence of any ground stone flakes, may suggest that debitage has also been discarded on that area, away from the primary manufacture place. In addition to that, exhausted or burned tools are often encountered, indicating that they were disposed during the final stages of their life-cycles. On the contrary, the Avgi II deposits from the same area have yielded many intact ground stone artifacts (75% of the tools attributed to that phase), among them many intact grinding slabs with their grinders, unearthed in the vicinity of various thermal structures, probably indicating the presence of active use surfaces.

The presence of intact ground stone tools, some of them probably located in situ, provides some indication of the activities that this area once has hosted. The versatile character of the ground stone tools suggests their involvement in a wide range of activities. Grinding tasks must have occurred in this area at a regular, perhaps daily basis. The presence of grinding slabs and grinders near thermal structures suggests that plant food processing and maybe cooking was practiced extensively at this open area. The small size of the grinding slabs, however, which would have hindered the production of large quantities of processed grain, indicates that these were probably used to cover domestic needs, and not for communal, large-scale events (e.g. feasts). Although the processed material may have served the nutritional needs of small groups (families or households), the presence of the grinding equipment in an open, unrestricted area, may suggest that these tools were shared between different families. Of course, these tools could have also been the equipment of specific households and, given their small sizes, could have easily been occasionally transported from the house interiors to the yards, acting at different social contexts and serving different social needs, during their biography. The traces of red pigments on the secondary used faces of some grinding slabs are indicative of their flexible character.

If we accept a primary depositional character for the assemblages of this phase, the numerous pebble tools, but also the percussion stones and the groove abraders, suggest that this area also hosted activities related to the manufacture or maintenance of objects and that it was not restricted to food preparation. Edge tools, on the other hand, could have been involved in a variety of intra site and off site actions, including tree cutting, wood crafting, butchery, bone working, shrubbery cleaning and digging (see Tsoraki 2007) but for the moment it is difficult to tell with certainty if any of these were practiced in this open area. Finally, the presence of some performs and debitage suggest that ground stone tool making and repairing was probably practiced here, but on a limited scale.

The study of the ground stone assemblage of Neolithic Avgi is still at its infancy and it certainly has a long way to go. The preliminary results have hopefully indicated the dynamic and versatile character of the material under study. More detailed and contextualized work is required in order to understand the complex biographies of these tools, approach their social meanings and investigate their role in the Neolithic society of Avgi.

References

Adams, J.L. 2002. Ground stone analysis. A technological approach. Salt Lake City: The University of Utah Press.

Bekiaris, T. 2007. Τριπτά εργαλεία από το Νεολιθικό Οικισμό της Μάκρης Έβρου. Unpublished M.A. Thesis, Aristotle University of Thessaloniki.

Bekiaris, T. 2008. Τριπτά αντικείμενα από το Νεολιθικό Οικισμός Αυγής Καστοριάς: Παρατηρήσεις πεδίου. On line paper at http://www.neolithicavgi.gr/?page_id=494&langswitch_lang=el

Bekiaris, T. 2010. Ground Stone Tools from Drakaina Cave: An Overview. On line paper at http://www.drakainacave.gr/index.php?option=com_content&view=article&id=70&Itemid=48&lang=en (also available in Greek).

Melfos, V. and G. Stratouli 2002. Η προέλευση των πρώτων υλών για τα τέχνεργα του οικισμού In G. Hourmouziadis (ed.), Δισπηλιό 7500 χρόνια μετά, 175–183. Thessaloniki: University Studio Press.

Perlès, C. 1992. Systems of exchange and organization of production in Neolithic Greece. Journal of Mediterranean Archaeology 5: 115-164.

Stratouli, G. 2002. Τα εργαλεία από λειασμένο λίθο, οστό και κέρατο. In G. Hourmouziadis (ed.), Δισπηλιό 7500 χρόνια μετά, 155–174. Thessaloniki: University Studio Press.

Stroulia, A. 2003. Ground Stone Celts from Franchthi Cave: A Close Look. Hesperia. 72(1): 1-30.

Stroulia, A. 2010. Flexible Stones: Ground Stone Tools from Francthi Cave, Fascicle 14, Excavation in Francthi Cave, Greece, Indiana University Press.

Tsoraki, C. 2007. Unraveling ground stone life histories: the spatial organization of stone tools and human activities in LN Makriyalos, Greece. Documenta Praehistorica 34: 289-297.

Tsoraki, C. 2011. Stone-working traditions in the prehistoric Aegean: the production and consumption of edge tools at Late Neolithic Makriyalos. In V. Davis and M. Edmonds (eds.), Stone Axe Studies III, 231-44. Oxford: Oxbow Books

April 2012